Microvast Holdings, Inc. will invest $504 million to locate its first polyaramid separator plant in Hopkinsville, Kentucky. The project is intended to be the world’s first mass production facility for the cutting-edge polyaramid separator technology, and will create up to 562 new full-time jobs.

“We are excited to announce this next chapter for Microvast, as we intend to build the world’s first mass production facility for our cutting edge polyaramid separator technology,” said Yang Wu, Microvast’s Founder, Chairman, President and Chief Executive Officer. “This material took over 10 years to develop internally and we believe it offers significant safety advantages compared to other polypropylene or polyethylene separator technology available today. We are pleased to expand our manufacturing footprint into Kentucky as it continues to position itself as a leader in EV manufacturing and are eager to work closely with the local community as we begin construction.”

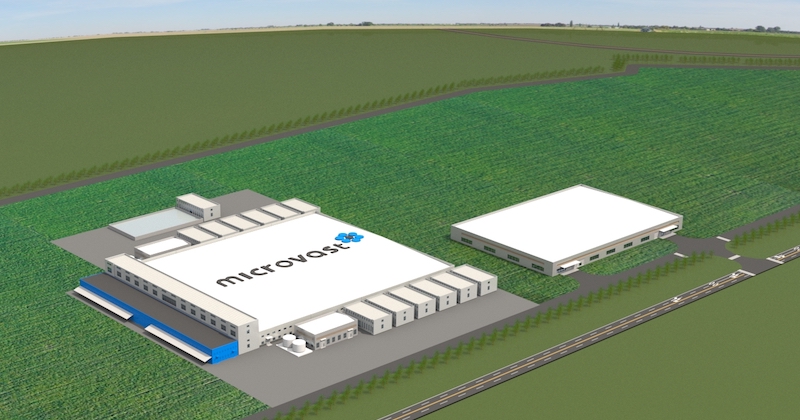

Texas-based Microvast — which designs, develops and manufactures lithium-ion battery solutions — will establish operations in a 350,000-square-foot building on a 100-acre site in Commerce Park II in Hopkins. Construction is expected to begin this year and be completed by March 2025. The campus, which will include a collaboration with General Motors, is expected to be funded in part by a $200 million grant from the U.S. Department of Energy (DOE) as part of the recent Bipartisan Infrastructure Law intended to develop a North American-focused electric vehicle (EV) supply chain.

Polyaramid is a high temperature-resistant, fire-retardant aromatic polyamide, which is commonly used in firefighting garments and insulating papers. The material was part of a United States Advanced Battery Consortium (USABC) technical assessment project, which independently confirmed through U.S. National Labs the polyaramid separator’s specifications and positive impacts to vehicle safety. This facility will help integrate the product into EV battery designs, including Microvast’s cells as well as those of other third-party battery manufacturers.

“We expect the safety advantages of our innovative, highly thermally stable polyaramid separators to transform high-energy lithium-ion battery development and drive significant value for the industry,” said Dr. Wenjuan Mattis, chief technology officer at Microvast.

Microvast’s investment helps solidify Kentucky’s position as a leader within the burgeoning EV sector, with significant investment throughout the past three years. Since June 2020, the commonwealth has seen over $10.5 billion in EV-related investments, with more than 9,700 full-time jobs announced.

“Kentucky continues to position itself as the top EV-related manufacturing location in the country,” said Governor Andy Beshear. “We are committed to creating an environment where the industries of the future can grow and thrive right here in the commonwealth, and Microvast’s investment is a huge step toward that goal. I want to thank local and state officials, as well as the company leadership, for bringing such an incredible project to Hopkinsville. I am thrilled to welcome Microvast to Kentucky and look forward to their future success.”

Toyota Boshoku America Inc. To Invest $225M, Create 157 Jobs

Also in Hopkinsville, Toyota Boshoku America Inc. (TBA) will invest more than $225 million to construct a new facility and create 157 jobs. The new facility will include a 365,400-square-foot building pad on 49 acres in Christian County. It will be the first TBA location globally to be considered a “Smart Plant.” The facility will employ innovative, cutting-edge technologies such as advanced robotics, planning and automation to streamline processes, reduce waste and enhance productivity to maximize efficiency and operations.

![[VIDEO] Get More for Your Business in Ardmore. Oklahoma](https://businessfacilities.com/wp-content/uploads/2024/02/maxresdefault-324x160.jpg)